Digital twinning use cases strengthen with AR, VR

More business leaders are realizing that digital twinning plus augmented reality and virtual reality helps them advance their digital transformation efforts. Take a look at how.

By Johna Till Johnson, Nemertes Research

More and more organizations have use cases for digital twinning. Adding augmented reality and virtual reality only increases that justification.

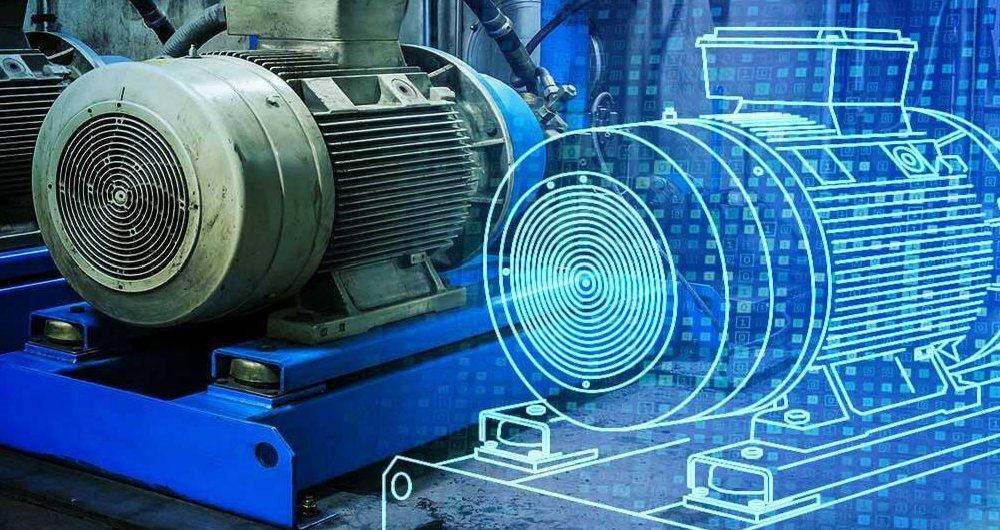

In a nutshell, digital twinning is the process of creating a highly realistic model of a device, system, process or product to use for development, testing and validation. Augmented reality (AR) and virtual reality (VR) come into play as well. For example, AR can show a digital twin on top of a physical machine and provide information a technician wouldn't otherwise see, and technologists can enter the VR of a digital twin to simulate various issues.

Many folks associate the use of digital twins solely with manufacturing. While it is true that manufacturing has pioneered the use of digital twinning, use cases exist in every industry. Additionally, there are digital twinning use cases in cross-industry applications such as infrastructure and automation.

To better understand the potential uses of digital twinning, AR and VR, take a look at the use cases in a handful of industries.

Manufacturing

Aerospace, automotive and general-purpose manufacturing firms use digital twins as part of overall product development. Here are some common uses:

creating design mock-ups to show how a finished product will work; fine-tuning product features and capabilities; defining requirements to provide guidance to component suppliers on component specifications, such as bolt size, shape and strength; testing and quality assurance; creating customer-requested modifications and other design personalization; creating operational and performance optimization; and predicting future failure modes so maintenance can be preemptively scheduled, and executing on other predictive maintenance goals.

Healthcare, retail and other human-centric industries

Companies that interact with customers can also benefit from digital twinning, which enables them to optimize patient care and customer service. Some examples include the following:

improving operational efficiency, such as using digital twinning to optimize the flow of patients or customers through a facility; improving user experience by using AR and VR focus groups to test how customers or patients experience a physical facility; improving layout and design of facilities; and refining products and services for optimal appeal to customers and patients. Supply chain and logistics industry Companies that are heavily reliant on their supply chain or logistics functions can see particular benefits from digital twinning. Examples include the following:

pre-testing the performance of packaging and packaging materials; optimizing routes and delivery processes; and improving handoffs between stages in a supply chain. General applications of digital twins, AR and VR One often-overlooked use case for digital twins, AR and VR applies to almost every industry: infrastructure performance and automation.

Digital twins of routers, servers, storage appliances and virtual machines can serve as testing grounds to explore performance or security vulnerabilities. The same goes for testing automated processes.

For example, let's say an organization is rolling out a new automated process for operating system updates and patch management for infrastructure devices. Network engineers can program the automation tool to roll out the update process on the twinned environment first. In this way, they can gather configuration and performance data and share that with technology operations specialists who can revise the process if it results in unforeseen impacts.

Facilities and technology professionals can also use digital twinning to model the physical environments of systems and appliances. For example, if an organization is building out its own data center, a digital twin can model power, heating and cooling systems against rack layout. Facilities professionals can use this to check for hot spots and make sure that all control panels are easily accessible by facility personnel.

While it is true that manufacturing has pioneered the use of digital twinning, use cases exist in every industry. Finally, organizations can use the digital twin to optimize human operational processes, such as mapping how technicians walk through the data center.

While these applications may seem futuristic, enterprise organizations are deploying them today. The infrastructure lead at a large financial services firm recently told Nemertes Research that the single most important initiative infrastructure engineers can engage in is implementing AR/VR and digital twinning in their infrastructure environments and automation testing.

A digital twin checklist for infrastructure automation

For enterprise technologists looking to get started with infrastructure digital twinning, what are the next steps? The outline below refers to a network digital twin, but the same recommendations can apply to other infrastructure components such as servers, VMs or containers and storage appliances.

Virtualize and automate all changes to the production network; that is, make sure that all changes to the production network happen through scripts and APIs. Stakeholders should allow no manual configuration. Using this automation, capture all network configurations in a version-controlled repository, such as Git. Use a tool like Jenkins to develop and deploy a continuous integration/continuous delivery process and workflow that includes forking the repository, proposing changes and having the tool pull down modifications. This creates scripts to implement the changes on the digital twin network, which consists of the configurations in the version-controlled repository. This involves pushing the changes out, testing that the changes are successful and notifying the network engineer that the changes are successful. Using Jenkins' capability, merge the repository and implement the changes on the production network. Review and sign off on the final state -- or, if needed, roll back the changes. Consider conducting predictive maintenance on the digital twin network regularly to get early warning of any performance, security or other concerns. Where appropriate, deploy proactive patching and upgrades.

Read full article here.